Fill out this short form to request 3D printing services, including design and production. Based on 2D or 3D designs, we can create high-quality, small batches of custom prototypes or parts, including 3D-printed bobbins for coils, tooling, machine parts, fixtures, and molds. We can also complete the full process of creating custom 3D printed bobbins or spools and making electrical coils or transformers with them.

A Full-Service Solution to Prototyping

3D printing (also known as additive manufacturing) is a great choice for anyone in need of high-quality parts in lower quantities for testing and prototyping purposes.

- Ask us to design a part, or send us your designs.

- Allow our team to 3D print it for you.

3D Printed Bobbins for Coil Winding

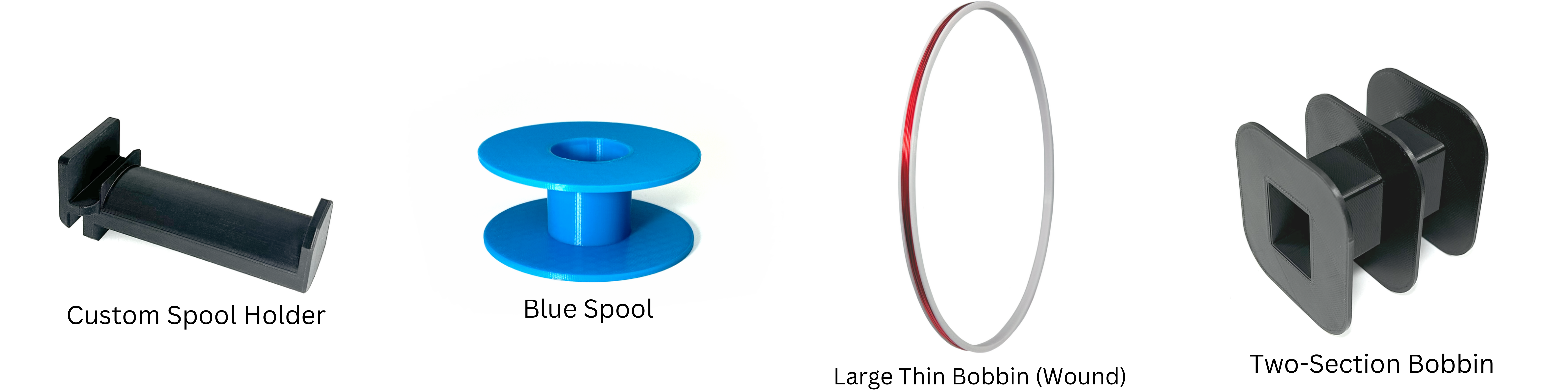

We offer 3D printing services to complement our custom wire services. If you need a custom coil, you may also need a custom bobbin to go with it. Some of our most popular requests are for 3D-printed bobbins and custom plastic spools. We’re also specialists in coil winding, so we can complete the entire process for you.

3D Printing for Electronics Prototyping

We specialize in 3D printing for electronics prototyping. However, we have the expertise and capabilities to complete a wide range of additional requests. Here are just a few of the electronics prototyping services we offer:

- 3D printed bobbins and custom plastic spools for coils, inductors, and transformers.

- 3D printed tooling for machines and machine parts.

- 3D printed molds, fixtures, and gages.

- Other 3D printed electronics.

- 3D printing of any and all plastic parts and prototypes.

3D Printed Tooling

If you need to test a new tooling idea or have another low-quantity tooling need, 3D printed tooling is a great choice. If tooling will be used for a limited number of machines, you may not be able to justify investing in a high-volume and expensive injection molding project. 3D printed tooling provides you with the high-quality tooling you need for your machine, affordably.

3D Printed Molds

If you need a specific plastic mold in an unusual shape or with specific dimensions, 3D printed molds are a great choice. 3D printing software can enable very specific designs that can be brought to life through additive manufacturing. 3D printed molds offer a great way to test multiple solutions before you settle on a single design for production.

Rapid Prototyping 3D Printing

Additive manufacturing companies like Remington Industries offer rapid prototyping 3D printing services to help your team elevate efficiencies. The time taken to 3D print a part or prototype will depend on various factors including the complexity of the design and the size of the printed object. Let us know you’re interested in rapid prototyping 3D printing when you request a quote, and we can also provide an estimated turnaround time for your project. Rapid prototyping may be completed in as little as one day, when completed files are provided.

3D Printing vs Injection Molding

We’re often asked for our thoughts on 3D printing vs injection molding. These two processes are both great options but are better suited for different stages in the design/production process.

- 3D printing services are a better choice for prototyping and testing new parts. It is an excellent solution for projects that are too low-quantity to justify the investment required for injection molding. You’ll receive just as high quality an output, but for a smaller number of parts. For example, you may decide 3D printed tooling is the best option for your project until you know the tooling design is working as desired on your machines.

- Injection molding is a better choice for high-volume production. Once a 3D-printed prototype is deemed successful, you may wish to invest in injection molding for a higher quantity output.

Why Choose 3D Printing for Prototyping?

Here’s a quick overview of why you may want to consider 3D printing for prototyping:

- 3D printing software enables you to create a prototype that meets your exact specifications and dimensions, and the output can be as detailed and complex as you need it to be.

- 3D printing allows for trial and error; it enables you to test multiple variations of a part or prototypes without investing in high-volume injection molding before you’re ready.

- 3D printing is a fast turnaround solution that can help you get your product to market faster and with confidence.

What is Additive Manufacturing?

Additive manufacturing is an industry term for 3D printing; the two terms are synonyms. Additive manufacturing is the process of creating a physical object using a 3D printer. The object is designed digitally using specialist CAD software. When the object is “printed” physically, it is formed layer by layer. There are various types of additive manufacturing, such as fused filament fabrication (FFF: extruding material), stereolithography (SLA: curing resin), and selective laser sintering (SLS: fusing powder). Our machine uses a material extrusion process.

A Step-by-Step Overview of the Additive Manufacturing Process

Additive manufacturing companies, like Remington Industries, are able to offer a full-service solution, including design for additive manufacturing and production of low-volume, high-quality prototypes. Here’s a brief overview of the additive manufacturing process:

- A 3D design is created, using Computer Aided Design (CAD).

- The machine is prepared for your unique project.

- The printing process begins; your object is created one layer at a time.

- Remington Industries can offer a post-print measurement of critical dimensions, cleaning, and inspection to guarantee a functional, defect-free part.

Talk to an Expert About 3D Printing Services

Interested in learning more about 3D printing for prototyping? Our team is based in Johnsburg, Illinois, and can help talk through your project and offer expert guidance. Contact us to request a quote for your project, and find out if 3D printing for prototyping is right for you.

Contact Us

In other words, whatever your custom requirement may be, it only takes one call to get experienced assistance.

Contact us by phone: (815) 385-1987

Contact us by email: sales@remingtonindustries.com | Contact Form

Mailing Address:

3521 N. Chapel Hill Road

Johnsburg, IL 60051 U.S.A.

FAQs

What kind of files do I need, and what is the maximum file size?

We can print from .STL, .STP, and .OBJ files, or we can work from a 2D drawing (.DWG, or .PDF) to create your 3D print. Please upload a maximum file size of 50 MB.

What are the maximum dimensions you can 3D print?

Our maximum build volume is 11.0×9.8×11.8 inches (280×250×300 mm). However, if you need a part that is larger, we can print multiple smaller pieces and combine them mechanically (e.g. using printed snap-fit joints) or with industrial-grade adhesives.

What colors can be 3D printed?

We can print in any color you request.

What materials can you print?

We can print parts in common materials such as PLA and ABS, plus more advanced materials like PA, PC, PLA-CF, PETG-CF, and ASA.