Working with our sister company Prem Magnetics, we use our high-quality wire to wind coils of many kinds. We are proud to work together to offer exceptional coil winding services, and provide our customers with the 100% tested coils they need. Submit the form below to request coil winding services:

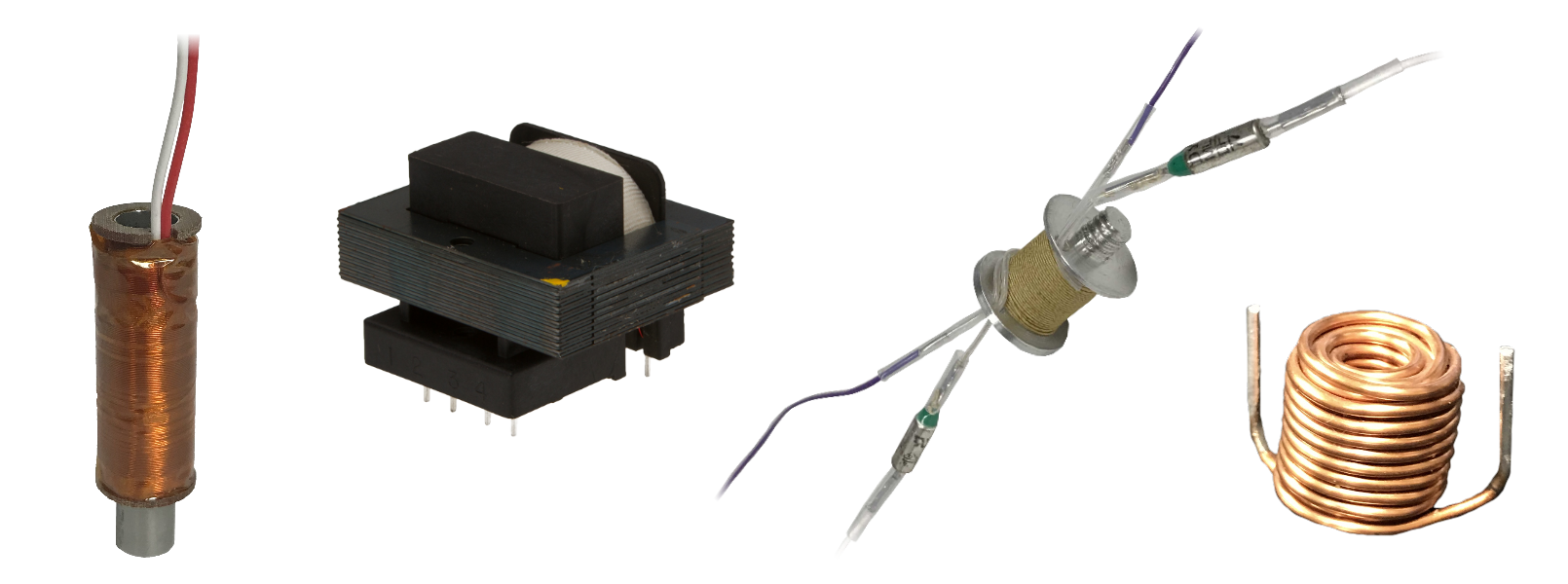

Custom Coil Winding

The coil winding team at our sister company Prem Magnetics is vastly experienced in manufacturing coils for the medical industry, audio equipment, electronics industry and more. Making use of our high-quality wire, Prem Magnetics is able to create custom coils for your application.

Purchase wire from Remington Industries or elsewhere and choose our team for custom wire services, including magnetic coil winding.

Wire available from Remington Industries includes:

• Hook Up Wire

• Magnet Wire

• Uninsulated Wire

• Any wire you need – via our Wire Procurement Services

We are here to manufacture high quality electromagnetic coils to your exact specifications.

Custom 3D Printed Bobbins for Coil Winding

Many of our customers that request coil winding services need custom bobbins too. We offer 3D printing services to create the custom bobbin you need, efficiently and affordably. If you only need one bobbin or a lower quantity of bobbins, 3D printing is the best solution when a standard bobbin isn’t available. Once you’ve tested your design, you may wish to move to injection molding for higher-volume production.

What is Coil Winding?

The manufacturing of electromagnetic coils is known as coil winding. Electromagnetic coils are an essential component within many circuits, thanks to the ability of the coil to create a magnetic field.

Electromagnetic coils are found in the following equipment and more:

- Transformers

- Generators

- Motors

- Loudspeakers

- Microphones

- Medical equipment

- Other electronics

There are a myriad of uses for electromagnetic coils, including any application in which an electric current must interact with a magnetic field.

.

Types of Coil Winding

There are many types of coil winding available, to meet a wide range of needs. Coil must be wound to precise specifications, to ensure it is well-suited to its application. Coil windings vary depending on:

- Differing strengths of magnetic fields required

- Inductance necessary

- Q factor

- Insulation properties needed

The type and geometry of the wound coil is very important depending on use case.

Our expert team can help you determine which type of coil winding is best suited to your project, and provide you with wound coils you can trust.

Popular coil winding services include:

- Linear winding

- Toroidal core winding

- Bifilar and trifilar winding

Coil Winding Machines

Our specialized coil winding machines enable us to take on a wide range of custom coil winding projects.

As custom coil winders, we have an experienced team with vast knowledge of coil winding, including precision and medical grade coils.

Why Choose Remington Industries and Prem Magnetics for Coil Winding?

Our high quality control standards and experienced team members will meet your exact specifications. Each part is 100% tested before it ships.

We are proud to use our coil winding expertise and wire winding technology to provide high-quality solutions to your electromagnetic coil needs.

Contact Us

Contact Remington Industries today for answers to questions about magnetic coil winding, and to get started with coil winding services you can trust. Alternatively, go direct to Prem Magnetics for coil winding, custom transformers, custom inductors and assemblies.

Contact us by phone: (815) 385-1987

Contact us by email: sales@remingtonindustries.com | Contact Form

Mailing Address:

3521 N. Chapel Hill Road

Johnsburg, IL 60051 U.S.A.